June 2025

| KARINA MULLER, PULA CONTRIBUTOR |

|

MAIZE FARMERS OFTEN WONDER WHAT HAPPENS TO THEIR MAIZE ONCE IT IS DELIVERED TO A SILO. PULA SPOKE TO KEY FIGURES IN THE MILLING AND DISTRIBUTION OF MAIZE TO SHED LIGHT ON THE PROCESS.

Eddie Ueckerman, sales director, and Luther Pretorius, general manager: systems and quality at AFGRI Milling, an operation that runs three maize mills and two grain mills in South Africa, explained that the company purchases maize from certified silos. AFGRI Milling is committed to supplying milled products to major companies that value social responsibility. As a result, traceability is a key requirement.

TRACEABILITY

Traceability refers to the ability to track a product’s journey from the farm to its final destination – be it the consumer, a retailer or a processor. In South Africa, traceability is gaining importance as consumers and industry players demand food safety, consistent quality and supply chain transparency.

While smaller private mills in rural areas may not always require this level of detail, traceability remains a cornerstone of large-scale, export-ready operations.

Source: https://www.roff.co.za/pages/posho-community-maize-mill

QUALITY EXPECTATIONS

Millers have clear expectations regarding maize delivery. According to Pretorius, the moisture content should be below 13%. This helps to reduce spoilage during storage and improves milling efficiency.

The maize must also comply with the Agricultural Product Standards Act, which requires the absence of:

Jan Jordaan, brand manager at Roff Milling, echoes these expectations and adds: ‘Clean, dry maize with the right moisture content does not just produce better flour – it protects your reputation as a reliable supplier. Proper storage and cleaning are basic steps that make a massive difference.’

He further notes that grain should be stored in well-ventilated, dry areas to prevent fungal growth and maintain grain integrity.

VARIETY PREFERENCES AND MILLING CHALLENGES

When it comes to maize varieties, hard-kernel types are preferred. Soft-kernel varieties can become mushy when water is added during milling, affecting the end product’s quality. However, as Ueckerman points out, newer high-yield varieties often have softer or smaller kernels, creating difficulties in the milling process.

While AFGRI Milling focusses on commercial maize, Jordaan emphasises that small-scale farmers can also deliver milling-grade maize – if the quality is controlled. ‘There are relatively affordable solutions for cleaning grain that can significantly improve its quality and market price.’

Maize ground to different textures – from coarse to fine.

WHITE VS YELLOW MAIZE

White maize is primarily used for maize meal. In contrast, yellow maize is used in processed products such as corn flakes, snacks, tortilla chips, beer and animal feed.

Different milling outcomes serve different markets:

COMMUNITY MILLING

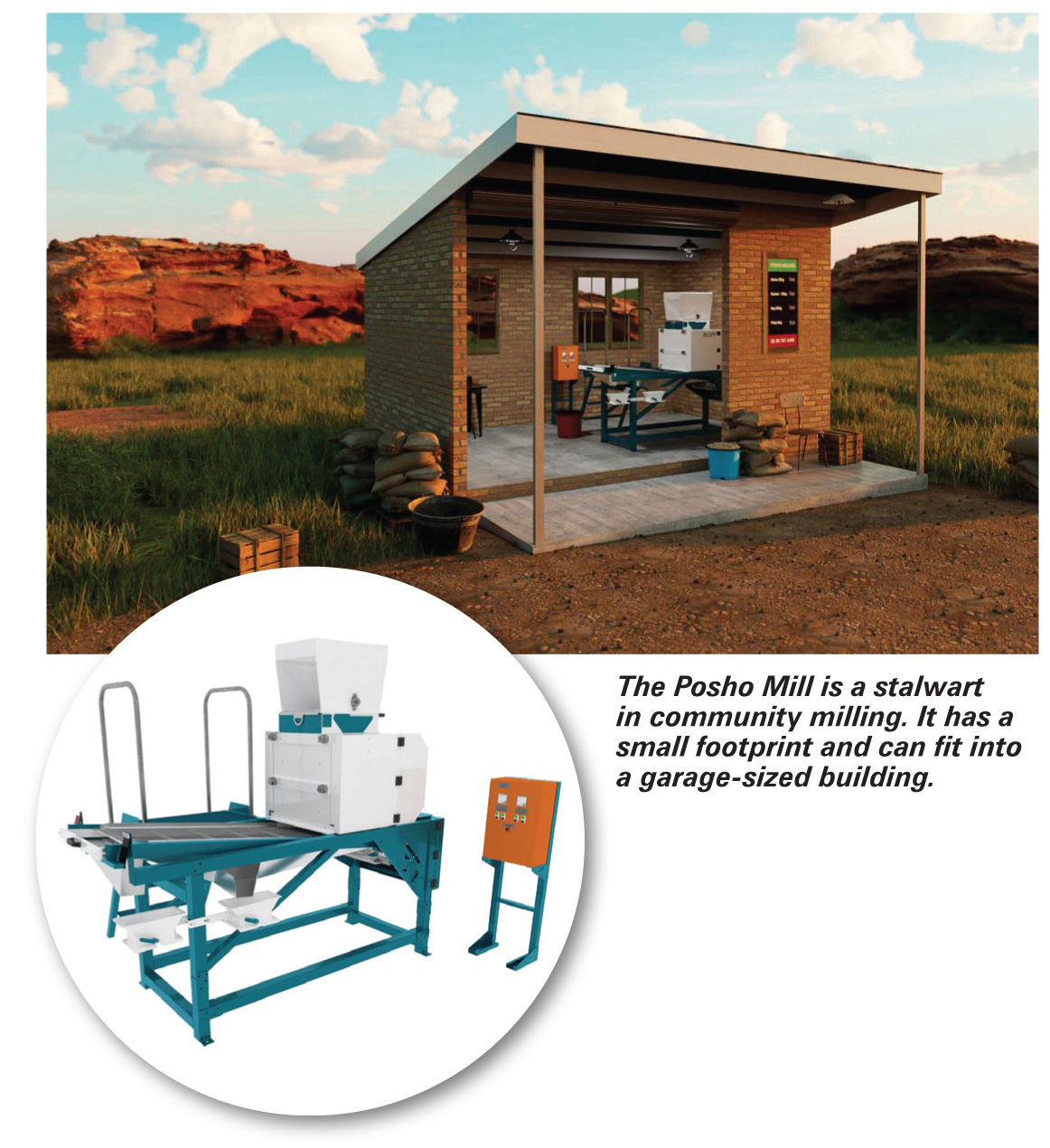

A significant development in the milling landscape is the rise of community milling, where small, local millers offer services directly to nearby farmers. Jordaan explains that a community mill can be as simple as a car garage with reliable electricity. Farmers save on transport and do not need to buy their own equipment. Plus, it keeps the money circulating within the community.

This model offers accessibility, affordability and empowerment for emerging farmers. However, challenges include initial set-up costs and infrastructure needs. Despite this, community mills often thrive by serving areas larger mills cannot reach efficiently.

According to Jordaan, equipment such as the Roff MK2 and Posho Mill have reliably served the community milling market across sub-Saharan Africa for over 30 years.

FUTURE OPPORTUNITIES

Jordaan highlights several key trends shaping the future of maize milling:

REGULATORY UPDATE

On 16 February 2024, the regulations relating to the grading, packing and marking of maize intended for sale in South Africa were updated (Government Gazette No. 50129). These changes aim to standardise maize quality, including new packing and moisture content requirements, ensuring consistency across the market.

Publication: June 2025

Section: Pula/Imvula