March 2023

| PIETMAN BOTHA, INDEPENDENT AGRI- CULTURAL CONSULTANT |

|

If farmers want to increase their profit and reduce their risk, it is a good idea to consider harvesting soybeans as early as possible to prevent shattering. Shatter losses due to brittle pods increase as the moisture levels of pods and grain drops. Therefore be on time with the harvesting of the soybeans.

The sound of soybeans shattering and no harvester in the field can break a farmer. Farmers understand that if soybeans shatter, a large portion of the yield is lost. Yes, sheep can eat these pips but the money is not available to go to the bank.

There are not only losses due to the brittle pods but the plant growth can also contribute to losses. Some plants and cultivars are known to produce pods very low on the soil. If the harvester table cannot harvest low enough, many soybeans are left behind. This makes it important to use the correct harvester header and to plant the correct cultivar.

Overestimation of the capacity of a harvester will result in large portions of the crop not harvested. However, harvesting low enough is easier said than done. Large stones in a field and very uneven fields can cause extensive damage to a harvester. Make sure that your harvester is insured for stone damage.

HEADERS

A flex header or flex draper is needed to harvest the low-growing and low-podded soybeans. This header will be able to follow the soil contours. This headers is a floating, multi-section flexible header with a split reel that allows the entire header frame, cutter bar and reel to follow the ground contours as a unit.

A flex draper header makes use of draper ‘belts’ that carry the crop to the feeder house. It feeds much smoother and allows farmers to cut a little later at night, due to the even feeding. Using the belt is also known to reduce soybean losses as the soybean plant is handled gently and the seeds don’t get lost in front of the harvester.

At the end of the year the soybean profit will determine a farmer’s bank balance. Farmers must calculate the yield in the tank when deciding which header to buy. Comparing the crop loss against the header price will determine this.

TIME IS MONEY

The time of day when a farmer starts to harvest is critical. As the soybean plant can absorb the dew moisture it gets sticky and loses its brittleness. This makes it difficult for the harvester to harvest. In the morning and evening it is typical for harvesters to break the cutter bare or the plants will get stuck around the threshing drum. This will have an effect on how many hectares can be harvested per day.

A rule of thumb is that a harvester with a 9-metre header over time will harvest between 20 hectares and 42 hectares per day – don’t expect it to be more. In order to harvest on time, a farmer needs 1,5 eight-row harvesters to keep up with one eight-row planter. It is important to understand that it is better to have surplus harvester capacity. This will help to increase the profitability.

COSTS

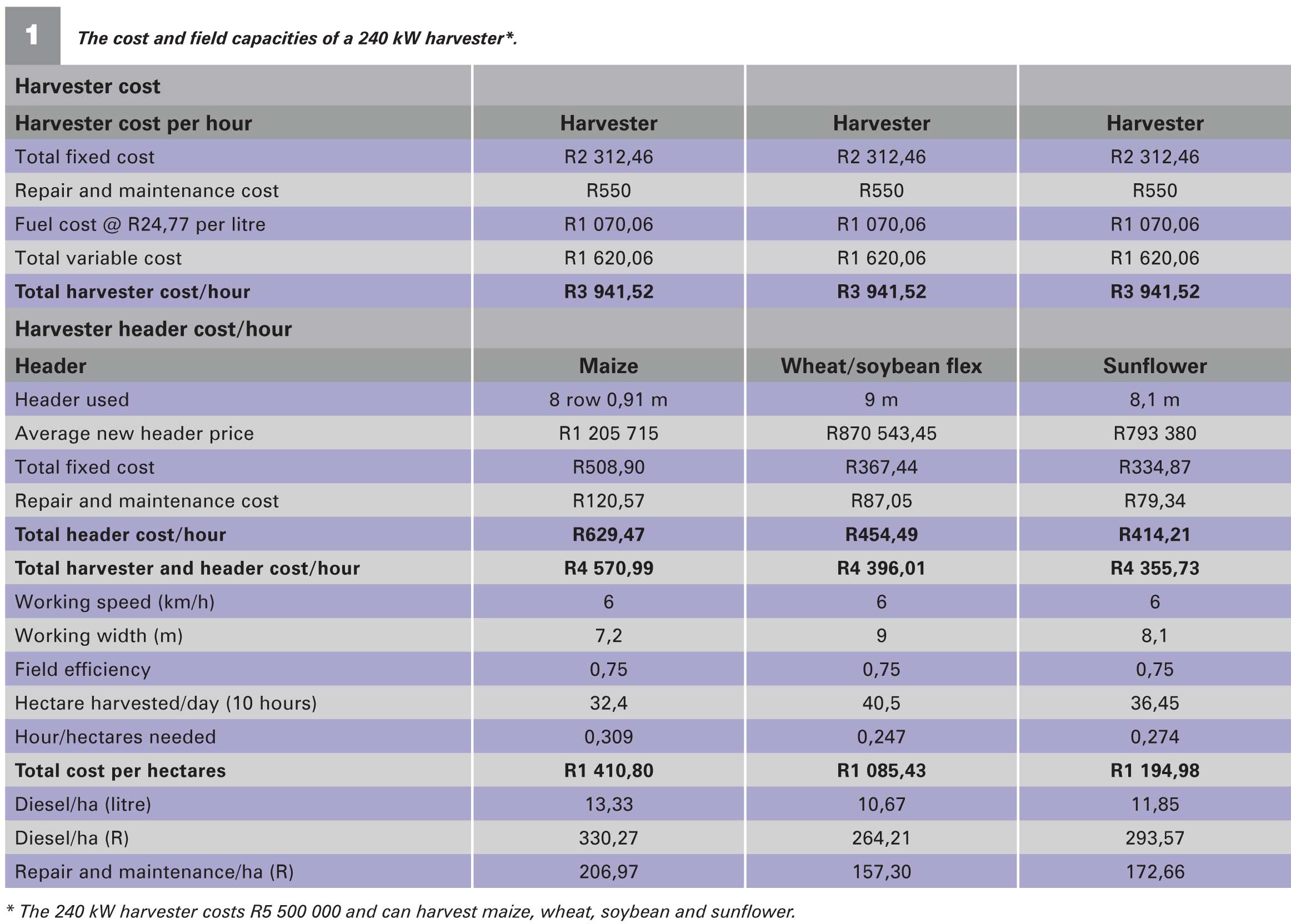

Harvesting a crop is an expensive action. In Table 1 the cost of maize, soybean and sunflower harvesting is shown.

At a speed of 6 km/h, 32 hectares of maize, 40 hectares of wheat or soybean and 36 hectares of sunflower can be harvested. As soon as the hours per day are reduced, the harvested hectares are also less. In the case of soybean, harvesting for ten hours per day is challenging. So do your calculations accordingly.

To be able to harvest for ten hours per day, repair and maintenance as well as services must be done according to the specifications provided by the manufacturer. Read the manuals and stick to it. If something breaks (and it probably will) make sure that the spares most likely to be needed are available. Prevention is better than downtime – especially in soybean harvesting, so service the equipment before the harvesting begins. It will save time.

Remember, a combine harvester normally works with an unloading wagon. The size of the wagon will be determined by the harvester. However, a farmer must remember that this unloading wagon needs an extra tractor and extra fuel. For a 240 kW harvester the diesel needed for the unloading wagon can easily reach 10 litres per hectare. Remember to add these costs to your calculations.

Also keep in mind that these unloading wagons are heavy and cause compaction.

SA Graan/Grain photo competiton – Karien Martinson, June 2021

Publication: March 2023

Section: Pula/Imvula