February 2023

| PIETMAN BOTHA, INDEPENDENT AGRI- CULTURAL CONSULTANT |

|

Maize, sunflower or soyabean headers are one of the most important components to harvest a crop effectively. If not properly maintained, the wear and tear will have an effect on the combine harvester’s performance and a number of kernels will end on the ground.

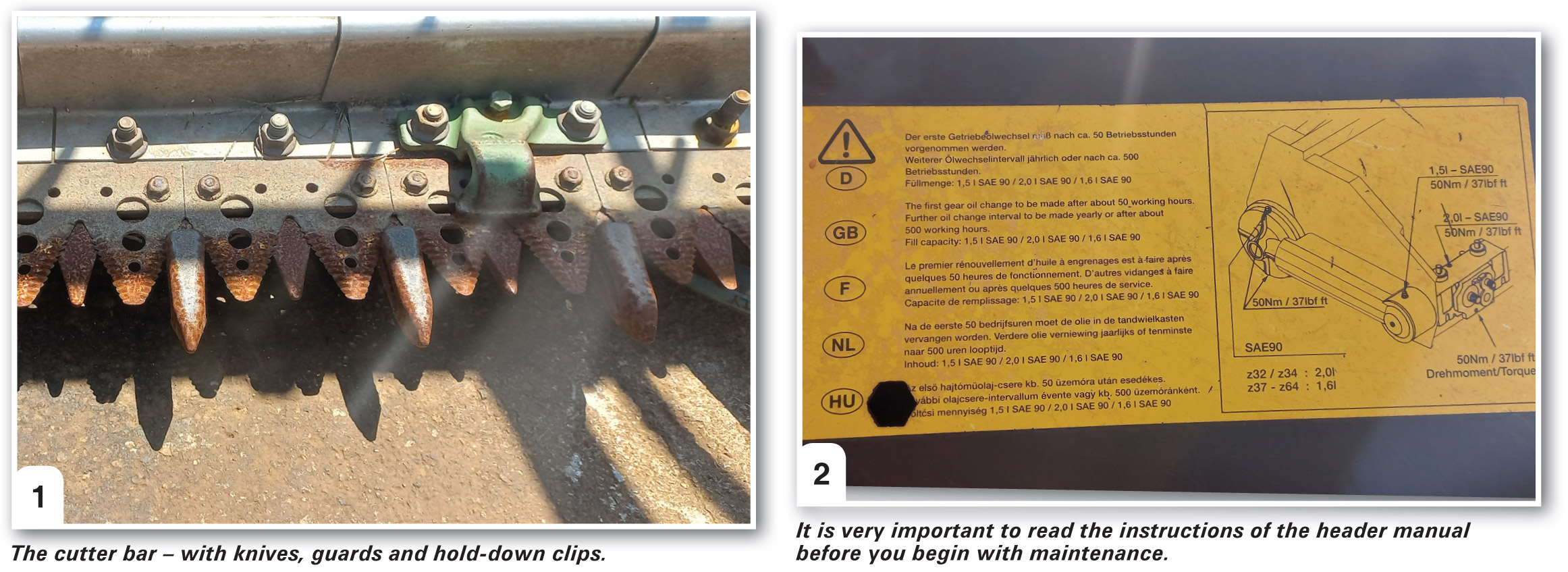

Make sure that the knives, guards, skid plates and hold-down clips are in good working order on the cutter bar (Photo 1). Remember, if you replace the knives, the guards must normally also be replaced. Make sure that the cutter bar stays in position and that it can move freely.

INSPECT THE MOVING PARTS OF THE HEADER

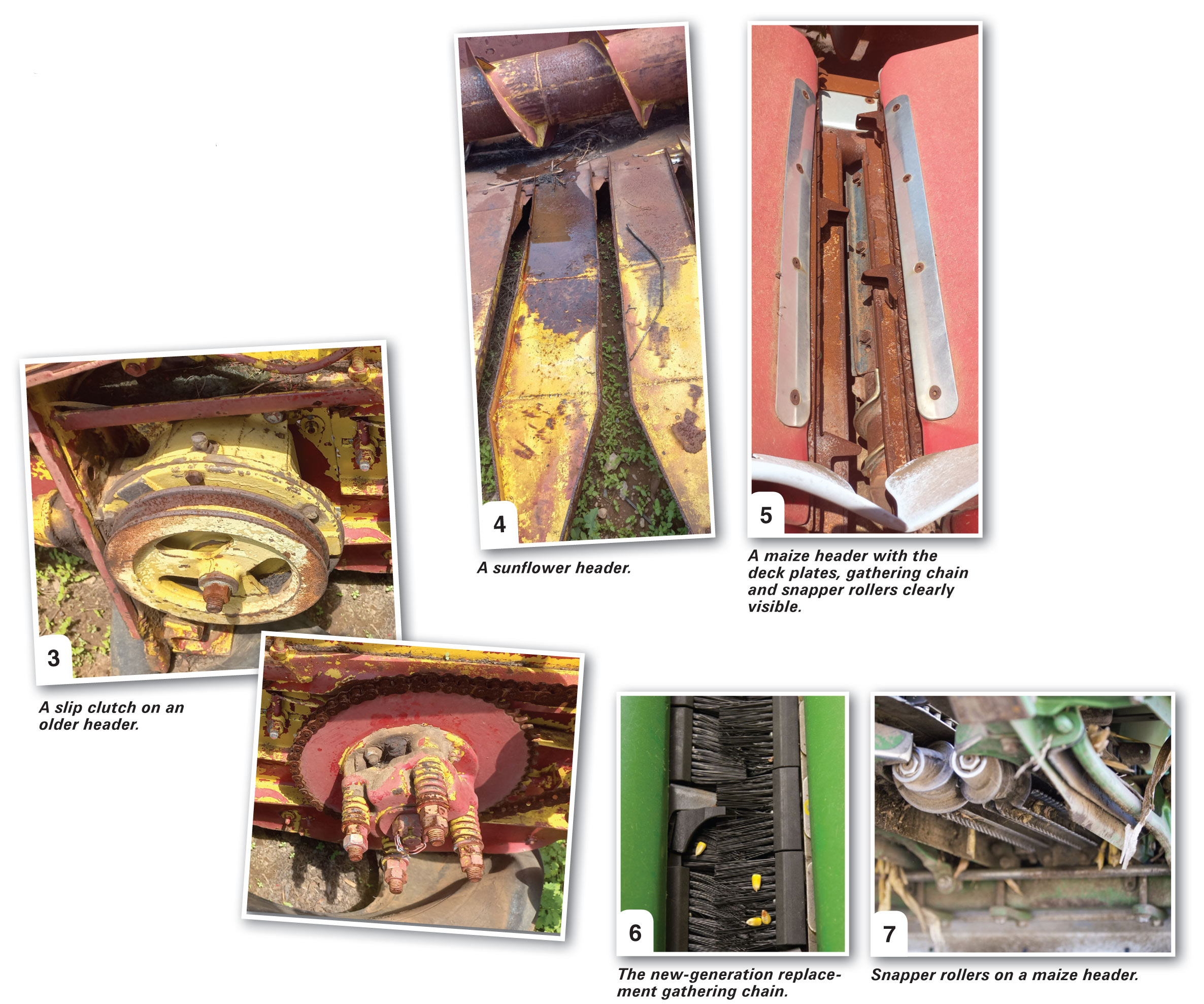

It is important to read the header manual (Photo 2) and to do the maintenance as required.

In the older type of headers, check the different clutches (Photo 3) and see that they are set according to the manuals. This can save you a lot of money.

Sunflower header

Sunflower header

For a sunflower header (Photo 4), make sure that the catch bords are in place and set according to the row widths. Ensure that the bords are tightened and set to catch the sunflower cobs. Check that the cutter bar is working efficiently.

The feed auger fingers, bushings, plastic guides, pins and sleeves must not be worn out, as this will influence the working of the header. If these components are worn out, the material cannot move effectively from the header to the combine machine.

Maize header

On the maize header (Photo 5), the important points to check are the deck plates, gathering chain, snapper and rollers.

Deck plates must be set to catch the cobs and kernels from falling down on the ground. If the deck plates can be adjusted, make sure that they are moving freely. Check for wear and tear on the links to adjust the deck plates.

The gathering chain is the chain that moves the material to the header feed auger. Check the tension on the chain and the wear and tear on the chain and sprockets. Make sure that the springs that keep the tension can move freely and are not rusted. Ensure that the drive gearbox is filled with oil or grease.

Photo 6 shows a gathering chain from 360 Yield Center. It is a gathering chain equipped with brushes to firstly absorb the shock of the heads on the cover plates and secondly to catch the loose kernels and feed them to the auger. This will help greatly with kernel loss.

Snapper rollers (Photo 7) are responsible for pulling the plant through the header. Make sure that the snapper rollers are set according to the manufacture norms. The speed of these rollers should be set according to the speed of harvesting. In the case of high-density maize, 360 Yield Centre markets a product named the chain roll. This snapper roller tears the plant material so that the material can decompose quicker.

For more information, contact your local dealer.

Publication: February 2023

Section: Pula/Imvula