February 2024

| PIETMAN BOTHA, INDEPENDENT AGRI- CULTURAL CONSULTANT |

|

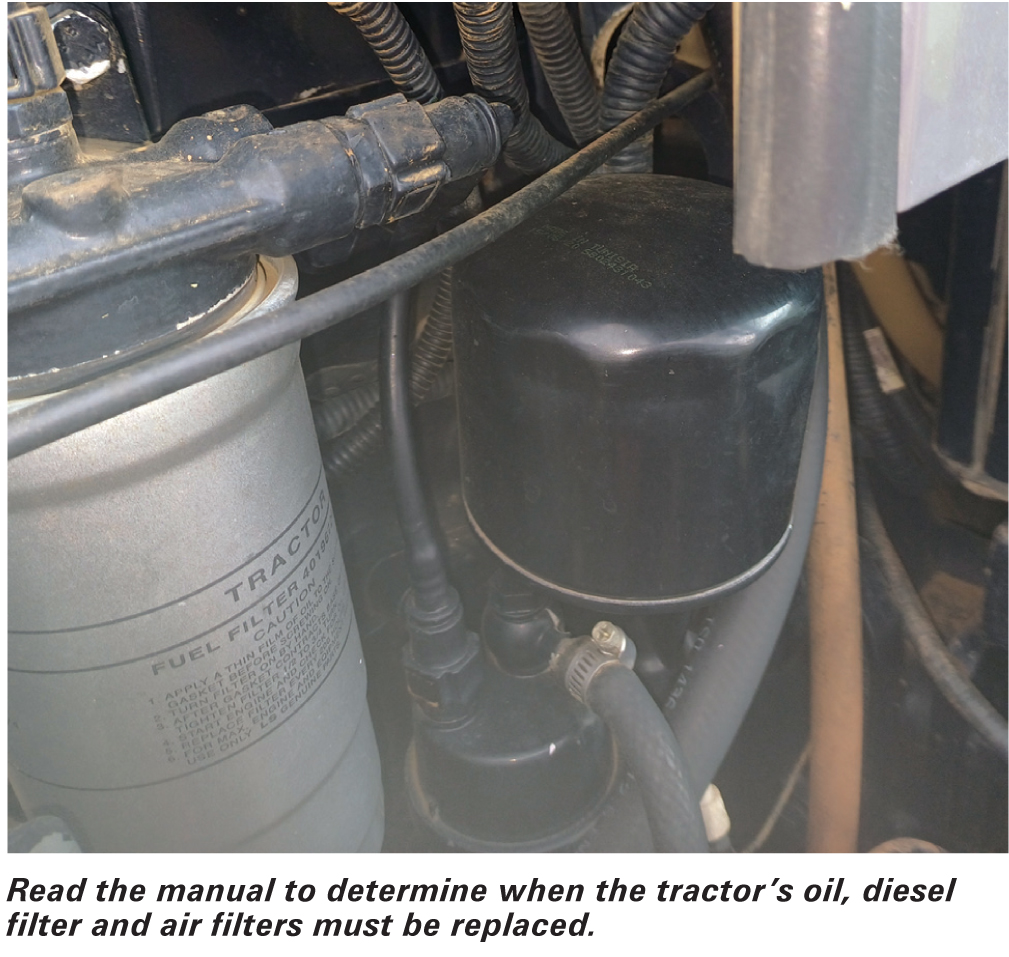

The breaking of farm equipment can be prevented by replacing wearing parts on time and by doing regular maintenance. Maintenance must be done daily before machinery starts operating and on scheduled times as prescribed by the owner’s operation manual.

It is very important for the owner to study the operation manual. If you don’t have an owner’s operation manual for the equipment, go to the local dealer and talk to the mechanic in the workshop regarding the maintenance of equipment.

Farm machinery and implements are expensive, and the cost of replacement increases every year. Equipment that breaks while in use will increase the farmer’s stress levels.

Farm equipment maintenance that is done on time, will help to optimise and execute time-sensitive tasks. If a tractor breaks down during planting, it is a disaster as planting is time sensitive. If you have only one single unit, the season can start as a failure with great financial losses. This is why modern farmers invest extra resources in the maintenance of agricultural equipment.

Farmers who follow regular maintenance practices, inspect their machines every day and have their documents organised to track equipment failure. Then they can be ready to replace damaged components ahead of breakdowns and avoid unplanned downtime.

BASIC FARM EQUIPMENT MAINTENANCE

The basic farm equipment maintenance tasks focus on servicing and storing equipment in the ideal environment to keep it in good condition for as long as possible. Here are some key tips that will help you understand what is needed to maintain farm tools and equipment:

Training and control

Follow a maintenance schedule

With a clear action plan, farmers can determine appropriate time intervals for regular maintenance. Normally it makes sense to do it before a major task begins and just after a task is completed.

The frequency of servicing is prescribed in the owner’s manual, but weather conditions, the local climate and other factors can cause the build-up of excess dirt and more damage to specific machines. When maintenance tasks and the condition of components are tracked, the maintenance schedule to service and protect the most vulnerable parts can be more frequent.

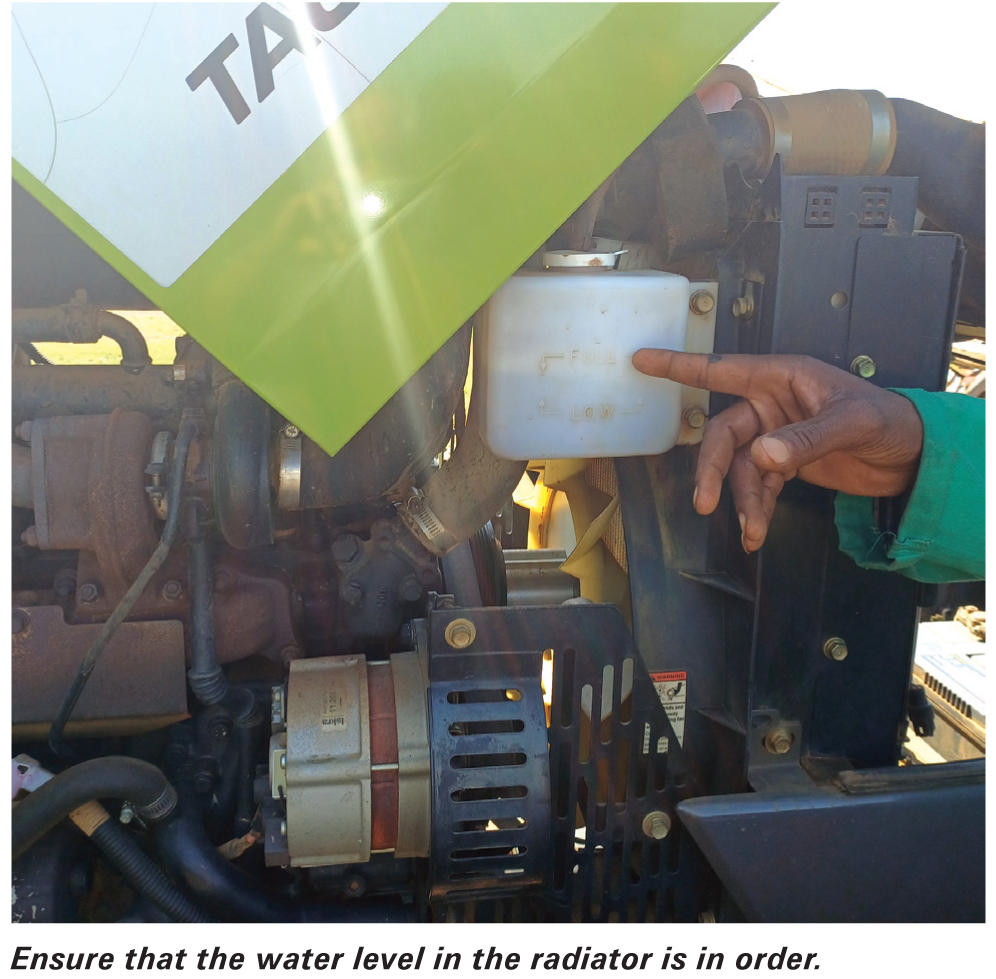

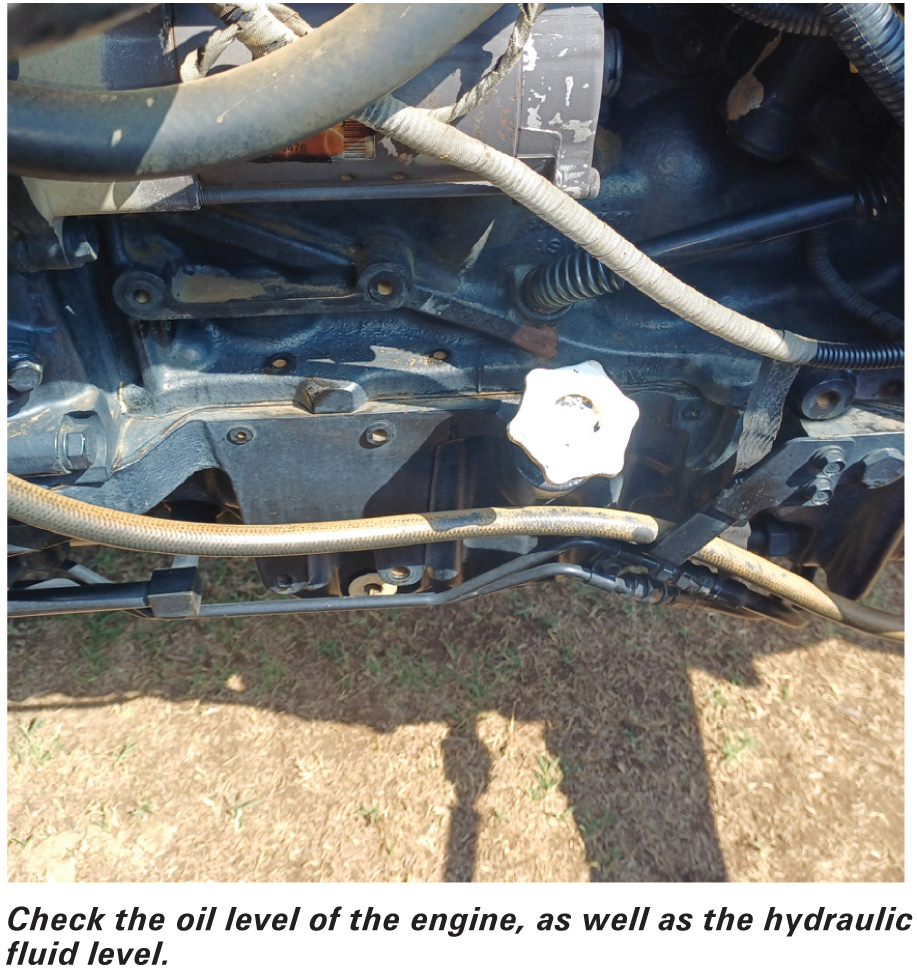

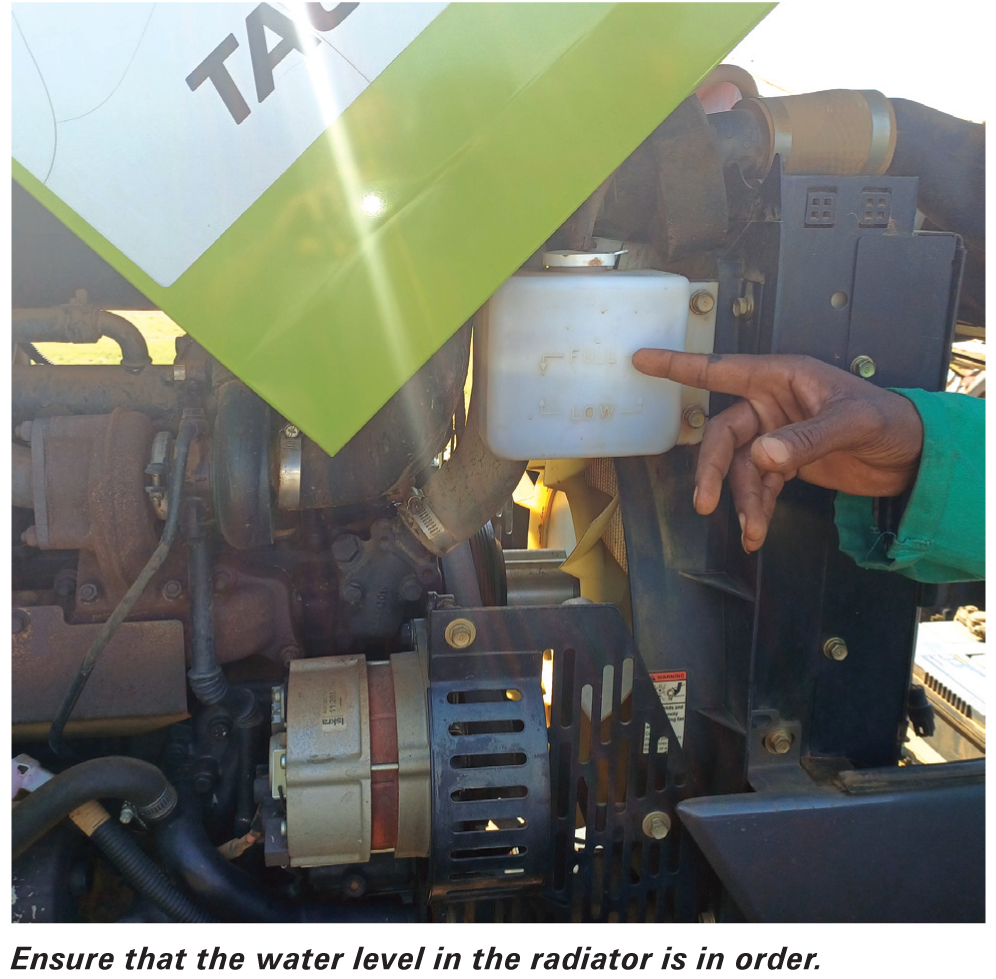

Fluid servicing and lubrication

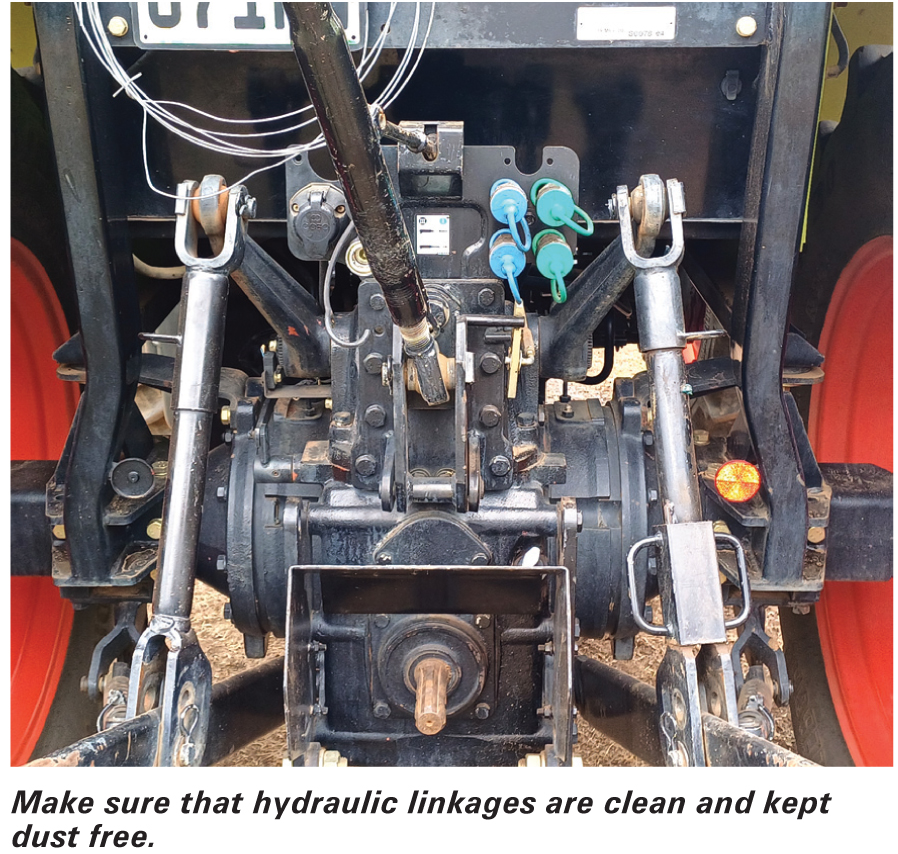

Hydraulic system maintenance

The hydraulic system is responsible for the mechanical work performed by heavy equipment machines. Follow these three important steps:

Equipment cleaning

Equipment cleaning is essential to prevent more abrasion and damage to farm equipment and their parts. Clean your machinery to remove accumulated dirt, replace air filters and oil filters, and perform regular oil changes to get rid of any contaminants. Certain machines may work slower or use much more fuel when the internal components are constantly affected by contaminants.

MORE ABOUT MAINTENANCE

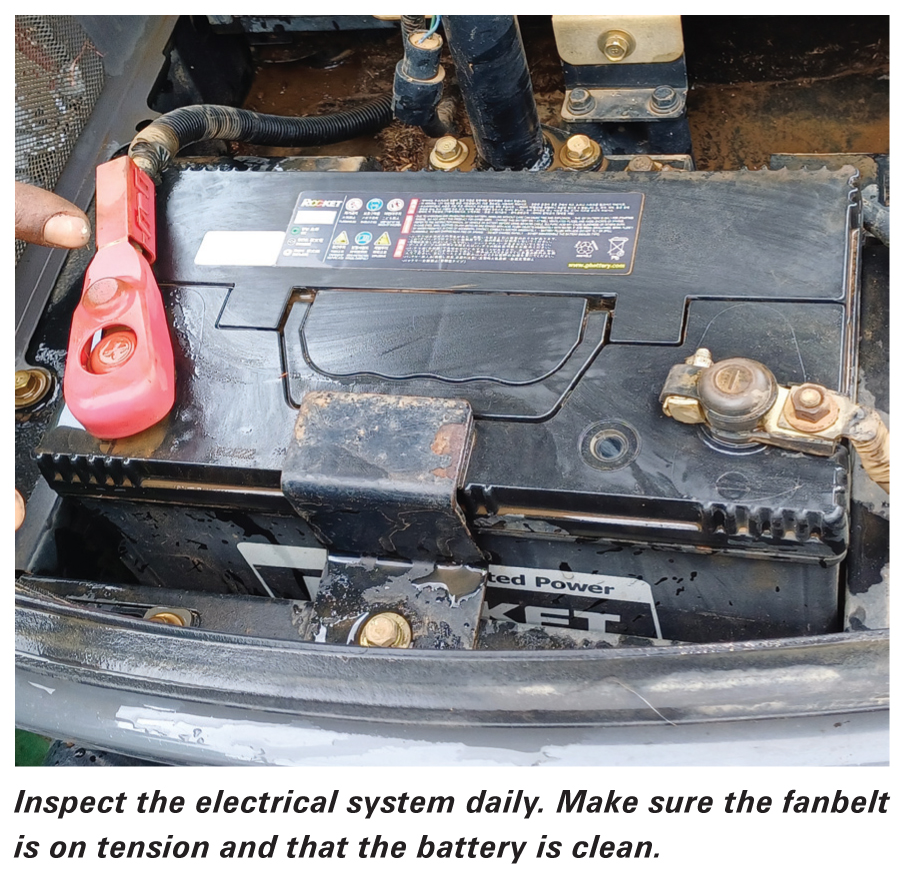

Old machinery is easier to maintain but identifying damages ahead of breakdowns is much more difficult. New tractors, combines and other machines have sensors and other electrical components that can minimise the need for repairs.

The most common signs that a farming machine needs servicing are visible damage to its exterior, strange noises and warnings on the control panel. However, sensors are not always right and their accuracy can get skewed by an accumulation of dust or dirt. In these cases, a regular maintenance calendar ensures that all machine components receive attention at appropriate time intervals.

Predictive maintenance studies the wear and tear of farming equipment to avoid unpleasant surprises. This involves documentation about farm equipment servicing procedures and monitoring how long a specific component survives on average. Predictive maintenance strategies focus on moving parts and keeping documents organised to make sure spare parts await repairs ahead of breakdowns.

FARM EQUIPMENT MAINTENANCE FRAMEWORK

FARM EQUIPMENT MAINTENANCE FRAMEWORK

To keep your farming machines in optimal condition, follow the manufacturer’s recommendations and compile a strict maintenance schedule. Here is an example of a basic and adjustable maintenance framework that should cover the main needs of most farming equipment:

Daily maintenance

Weekly maintenance

Seasonal maintenance

Seasonal servicing includes extra cleaning and fluid servicing during the winter months or other periods when the environmental conditions may cause extra damage to farm equipment. Every few months, certified technicians should replace filters and do thorough tests on the machine’s fuel consumption, handling and safety.

Annual maintenance

A mechanic can perform a thorough engine inspection and comprehensive testing of the hydraulic system annually. All changes, repair predictions and unexpected behaviour are documented. If the farm is using farm equipment software, IT specialists must inspect the sensors, install updates and troubleshoot any other issues.

IN CONCLUSION

It is much cheaper to repair and maintain equipment than to buy new equipment. Breakdowns in a critical period can lower your income and no one can really afford this.

For more information, contact your local machinery dealers and trained mechanics.

Publication: February 2024

Section: Pula/Imvula