July 2022

| PIETMAN BOTHA, INDEPENDENT AGRICUL- TURAL CONSULTANT |

|

Soil sampling is the basis of all optimal fertiliser and lime recommendations to maximise the yield and profit. When the soil potential, soil sampling and laboratory analyses for nutrient results are available, it is possible to determine the optimal liming or fertiliser programme.

METHODS

If soil sampling is not done correctly, the results will not reflect the status in the soil and as a result the optimal yield will not be reached. Due to the band placing of fertiliser and because cultivation practices usually do not mix the fertiliser effectively throughout the soil, plant nutrients are often not distributed evenly in the soil. It is thus vital to take care that soil samples are taken correctly.

Different soil sampling methods are published in the Agricultural Research Council’s (ARC’s) Maize Information Guide. Try to get hold of this publication, as it contains very good information.

Consult your fertiliser representative before taking the samples and make sure about the method.

TAKING SOIL SAMPLES

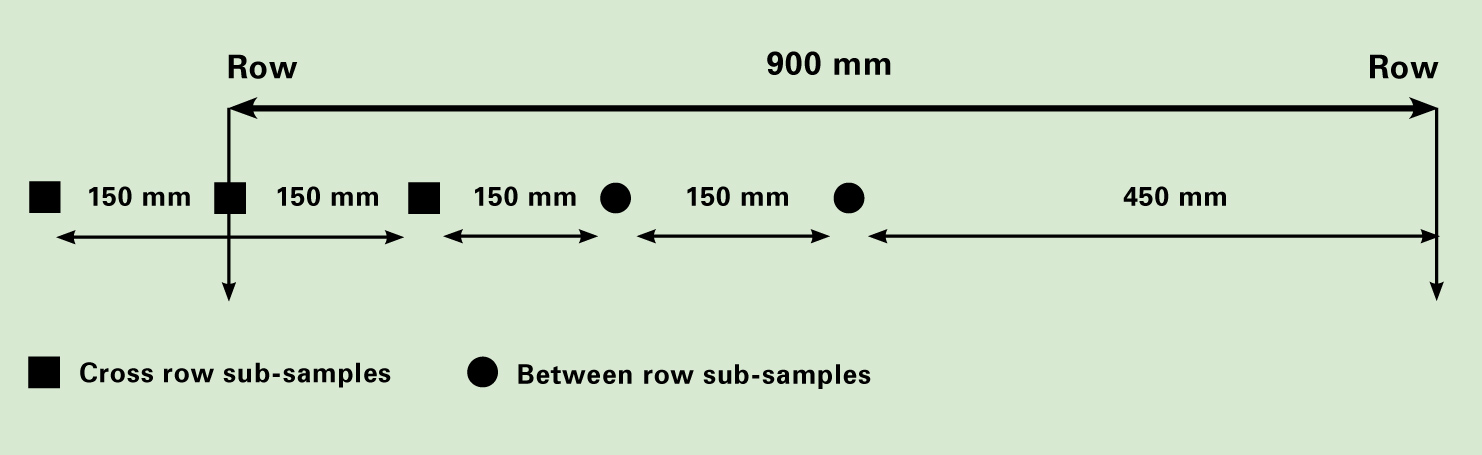

Soil samples must be taken after harvesting and before the first tillage operation is done. Representative samples of a 300 mm wide band over crop rows are analysed separately from between-row samples, as illustrated for a row width of 900 mm in Figure 1.

A soil sampling method for conditions where residual nutrients and soil acidity are not homogeneously distributed.

In total, five samples are taken – three across the row and two within the row.

Cross-row subsamples (■): The three samples are taken across the row so that the fertiliser band can be sampled. The three samples represent a band of ±300 mm.

Between-row subsamples (●): Two samples are taken in this area. One soil sample is taken exactly in the middle of two rows (450 mm from the row for a row width of 900 mm). A second soil sample is taken exactly in the middle of the cross-row subsample (■) and the between-row subsample (●) (300 mm from the plant row for a row width of 900 mm).

Soil samples must be handled correctly. Samples should be air-dried or frozen if nitrogen (N) analysis is required and samples cannot be delivered to the laboratory within 24 hours. In all instances, samples should not be exposed to direct sunlight. A soil mass of between 500 g and 1 000 g is required for each sample for analysis.

THE MANAGEMENT OF SOIL ACIDITY

Acidity is determined from the soil sample information and can also be seen in soil profile studies. Maize and oilseed production is limited by soil acidity only when the toxic levels of elements such as aluminium (Al) and manganese (Mn) are present and not necessarily a low pH.

Al toxicity is predominantly associated with soil acidity, while Mn toxicity is rarely associated with soil acidity – although both forms of toxicity can sometimes occur simultaneously.

The danger of Al toxicity in maize only exists when the pH (KCl) is below 4,5, or the pH (H2O) is below 5,5. Al toxicity is determined by the ratio of Al and hydrogen (H), to the total of potassium (K), calcium (Ca), magnesium (Mg), ions. This ratio, expressed as a percentage, is known as acid saturation.

Yield losses will increase as acid saturation increases above 20%, since the water and nutrient uptake are then impaired. No grain yield is expected at 80% acid saturation. Under conditions where both Al and Mn toxicity occur, Mn toxicity will be sufficiently neutralised if soils are managed below 20% acid saturation.

Lime is used to correct the pH and acid saturation levels. The lime requirement is aimed at reaching acid saturation levels of between 0 and 15%, to provide a buffer against re-acidification and Al toxicity.

However, the managing of acid saturation below 15% should be thoroughly considered. Lime application, more than what is necessary, to lower the acid saturation to 0%, for instance, is a costly process.

It is, however, important to determine up to what depth soil acidity prevails in the soil and to what depth it should be neutralised before the lime and gypsum rate is calculated.

TYPES OF LIME

Dolomitic and calcitic lime are available in the market. The Mg status of the soil will determine whether dolomitic or calcitic lime is needed.

Dolomitic lime is recommended in favour of calcitic lime when the Mg status of the soil is low (<40mg kg-1) or relatively low in comparison with the Ca status, unless the Mg requirement can be met through the use of Mg containing fertilisers. Compare the cost of the different lime sources. Ask the fertiliser representative to help you.

A well calibrated lime spreader is needed to apply the lime. Apart from quality, the lime reaction in the soil is highly dependent on mixing the lime thoroughly with the soil. This is achieved by first disking, then followed by ploughing or deep ripping. If it is possible, lime should be applied and worked in at least two months prior to planting to ensure that the lime reaction is complete when planting.

Publication: July 2022

Section: Pula/Imvula