April 2023

| DR BRADLEY FLETT, ARC-GRAIN CROPS, POTCHEFSTROOM |  |

Groundnuts, like all legumes, are important in fixing atmospheric nitrogen in the soil, a critical and often limiting nutrient for other non-leguminous crops in degraded or nutrient-poor soils. This makes it an excellent rotation or intercrop with maize in nutrient-poor sandy soils.

The groundnut (Arachis hypogaea L.) is an important food and fodder crop in farming systems of developed and developing countries. The seed is high in oil (close to 50% for many varieties) and protein (~26%) and is an important source of vitamins and dietary fibre.

In South Africa, groundnuts are primarily produced by large-scale commercial producers and subsistence farmers in certain parts of the country. Of the groundnuts produced by large-scale commercial producers, roughly 80% is used for consumption, whereas the rest is crushed.

Groundnuts are consumed as groundnut butter, crushed and used for oil, or simply consumed as a confectionary snack (roasted, salted or in sweets). Resource-limited farmers, especially in the northern and eastern parts of South Africa, grow groundnuts mainly for their own consumption. Groundnuts are an important source of nutrition in the northern KwaZulu-Natal and Mpumalanga areas.

The crop can also contribute to more viable and sustainable cropping systems in other parts of the country. Recently, researchers at the ARC-Grain Crops have received reports from processors regarding high levels of contamination and high aflatoxin levels in groundnuts resulting in serious financial losses to the local industry.

PRODUCTION OF AFLATOXINS

Many agricultural commodities are susceptible to several diseases caused by fungi, viruses and insect pests. Fungi survive in the environment (soil, air and water) and can easily find their way into crop products, especially when prevailing weather conditions are suitable for infection.

Some fungi can contaminate certain crops with toxins they produce that are called mycotoxins (myco = fungus; toxin = poison). The fungi Aspergillus flavus and Aspergillus parasiticus are the most common sources of contamination and mycotoxin production (aflatoxin) in groundnuts the world over (Photo 1).

Aspergillus spp.-infected groundnuts in the pod showing typical yellow/green fungus growth on the nut and the pod.

Photo: Dr Ranajit Bandyopadhyay, IITA, Ibadan, Nigeria

When aflatoxins are consumed via contaminated crops/products, they can have several negative health effects on humans and livestock. Despite a lot of funding being poured into research projects to control this disease and the production of aflatoxins, high incidences of aflatoxins causing disease in humans and animals worldwide are still being reported.

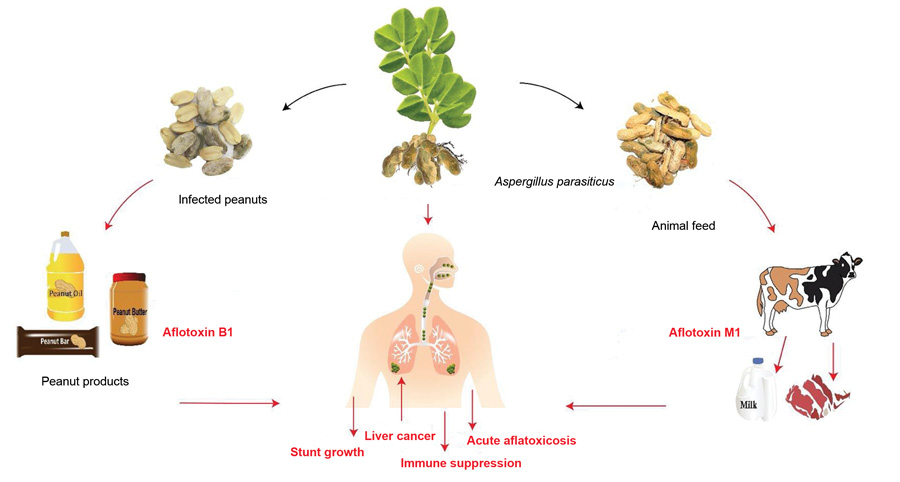

In groundnuts, high aflatoxin levels pose human health risks and are also a barrier to expanding trade and commercial use of groundnuts both locally and internationally. Eating food contaminated with aflatoxins leads to aflatoxin poisoning called aflatoxicosis. Regular consumption of low dosages for a long time (chronic exposure) leads to liver damage, immune suppression, malnutrition and stunted growth in children, while sudden high-level ingestion of the toxin can lead to death (Figure 1).

Sources of aflatoxin occurrence and its flow in the food chain to affect humans.

Aspergillus spp. infection and aflatoxin contamination are more evident where there are high temperatures, high moisture, moisture stress, poor harvest and post-harvest management and inadequate storage structures (Photo 2).

Although there are several control measures for aflatoxins, these are, unfortunately, not always effective. Control measures to be considered include several practices but integrating these practices into a disease management system is optimal in reducing infection and aflatoxin production.

Groundnuts harvested at Vaalharts showing Aspergillus spp. infections.

Photo: Maria van der Merwe, ARC-Grain Crops, Potchefstroom

PRE-HARVEST AFLATOXIN MITIGATION STRATEGIES

Use of resistant varieties: The most effective strategy for the control of aflatoxin contamination is the use of resistant varieties. At present, no groundnut variety is completely resistant or immune to Aspergillus species, but moderately resistant varieties are available for production. Nevertheless, this requires the continued screening of new groundnut varieties that enter the market. Some cultivars may show reduced Aspergillus infection, but they are susceptible to aflatoxin accumulation.

Timely irrigation: Groundnuts in South Africa are primarily produced on dryland fields. When climatic conditions are so that temperatures remain high during the groundnut growing season, infections may increase. High temperatures and drought create conditions conducive for A. flavus and A. parasiticus infection and aflatoxin production. Therefore, it is recommended that timely irrigation of the crop for pathogen management be considered where possible. Irrigation not only relieves drought stress, but also decreases soil temperature.

Commercial bio-control products: The application of bio-control agents can effectively control A. flavus and A. parasiticus invasion and aflatoxin production. This is where non-aflatoxin-producing strains are used as a bio-control system. Although these strains infect the groundnuts, they inhibit the growth of aflatoxin-producing pathogens in the groundnuts when preventatively applied.

Calcium: The application of calcium has been shown to be able to reduce levels of aflatoxin contamination in groundnuts.

Insect management: During the crop growing season, various insects can transfer A. flavus and A. parasiticus propagules (spores) from infected pegs and flowers to healthy plants. Also, insect-infected groundnut kernels are more likely to experience pre-harvest Aspergillus infection and aflatoxin contamination. Therefore, the scouting and timely management of groundnut-infesting insects are an important control strategy. Insects can also infect harvested products during storage. During this stage, insect pests can be controlled by applying chemical pesticides.

Early harvesting: Timely harvesting can limit the level of aflatoxin contamination. Rain late in the growing season generally leads to an increase in fungal growth and aflatoxin contamination. Early harvesting will differ from area to area, taking into account each area’s prevailing weather conditions. Early harvest is not possible in certain areas and may not be the most economical decision, depending upon production conditions. Producers need to consider the impact of all harvesting decisions on resulting crop economic value.

Rotation: Groundnut rotation with a non-host crop is an effective strategy for breaking the infection cycle to reduce Aspergillus inoculum in the field. When selecting a suitable crop for rotation, most importantly, the crop should not be a host to insect or fungal pests that infect both crops. Graminaceous crops, except for maize which is a known host, would be the most suitable rotation crop for groundnuts.

Cultural practices: The application of farmyard manure and lime reduces pathogen infection and aflatoxin accumulation in groundnuts.

Weed management: Certain weeds as well as volunteer crops, such as cowpea and maize, act as alternate hosts to Aspergillus species. Therefore, the proper management of weeds is a vital disease control strategy.

POST-HARVEST AFLATOXIN REDUCTION STRATEGIES

The post-harvest and pre-processing period is vital for groundnuts in terms of minimising pathogen growth and aflatoxin production. The following storage management strategies focus on reducing fungal inoculum by creating an environment that is non-conducive for infection.

Storage conditions: Generally, aflatoxins are more concentrated in groundnut seeds. Aflatoxin-producing pathogens infect stored seeds and produce toxins when the pod moisture level is above 8% and the ambient temperature exceeds 25°C. Dry pods to 7% moisture content to control the growth of aflatoxin-producing pathogens. After drying, pods can be safely stored at 70% relative humidity and between 25°C to 27°C temperature for nearly one year. Insects and pests can infect groundnuts during storage and should be controlled via the application of chemical pesticides.

Equipment sanitisation: Pathogens can survive in the soil or mud attached to harvesting equipment. Remove soil from harvest equipment before exiting the field to limit the spread of pathogens from field to field. Harvesting and drying equipment, including storage bins, should be properly sanitised before each use.

Packaging: Packaging material and processing significantly influence aflatoxin production in groundnuts. Quality deterioration and aflatoxin production in groundnuts can be controlled by using hermetic zero oxygen packing.

Separation of infected and healthy pods: Groundnut pods or kernels damaged by insect pests or mechanical injury during digging or threshing are more susceptible to fungal infection during storage. Identify and destroy the damaged, shrivelled, misshaped, or contaminated pods and seeds.

Producing aflatoxin-free groundnuts ensures food safety. The health and economic well-being of a producer and consumers of groundnut products are an important investment in the agricultural sector. The use of good crop production practices and post-harvest handling techniques together with non-toxigenic strains can effectively reduce aflatoxin contamination and maintain the quality of the produce. Such efforts would then open up opportunities for producers to access rewarding markets that currently have stringent quality standards.

REFERENCE

Alam T, Anco DJ and Rustgi S, 2020. Management of Aflatoxins in Groundnut. Available at https://lgpress.clemson.edu/publication/management-of-aflatoxins-in-peanut

Publication: April 2023

Section: Pula/Imvula