Do maintenance before harvesting

March 2024

PIETMAN BOTHA,

INDEPENDENT AGRI-

CULTURAL CONSULTANT |

|

A pre-harvest combine maintenance checklist can help a lot with the preparation for the coming harvest season. A checklist should cover anything that has been overlooked or gone uninspected since the last harvest – technology, fluids, filters and more.

For any combine owner, productivity is important. Focus on the following productivity-enhancing tips and make sure your combine is ready to hit the fields this harvest season.

DO AN EFFICIENCY CHECK

When the harvest is going smoothly, everything seems wonderful, but are you really achieving your highest yields if your equipment is not properly set up and calibrated for a peak performance? Grain lost on the ground is lost forever.

The following three steps will ensure that you get the most grain possible in the tank:

- Invest in paddle tines, especially when harvesting soybeans and wheat: With their unique ‘five-finger’ design, anti-debris build-up and easy-to-install snap-on features, paddle tines can help to gather short or sparse crops more accurately. This means greater returns and improved feeding of crops such as soybeans and wheat.

- Check your feeder latch: Before you harvest, check your feeder latch and make sure it has some preload in one of the notches when the head is attached. This helps to strengthen the clamp between the head and feeder, so there are no crop loss gaps.

- Clean your feeder house connections: Cleaning and inspecting your feeder house and feeder house connections and adjusting the feeder chain to its optimal tension will help you to improve efficiency out in the field. Keep the feeder running in a high position for maize or soybeans and low for wheat.

INSPECT AND PROTECT TO MAXIMISE UPTIME

The only thing worse than sub-optimal equipment performance is an equipment breakdown. You may have done everything in your power to harvest at the right time and in the right field conditions, but if your equipment breaks, all your preparation and planning can quickly go to waste.

Protect your equipment

Take these equipment-protecting tips into consideration before you head out this harvest season:

- Inspect machine concaves: Inspecting machine concaves can safeguard against poor threshing. Not sure where to start? Consult your dealer for a thorough equipment examination.

- Know when to replace rasp bars: Replacing rasp bars at the right time is one of the most effective ways to prevent grain damage. Signs such as twists, breaks, chips, cracks or other damage can mean a replacement is due. Here is the best way to tell: If you can’t read the number on the bolt head anymore, it’s time to change your rasp bar with a new one.

- Stalk stompers: Stalk stompers are designed to protect tyres from costly stubble damage, helping you to avoid downtime and improving your overall harvest performance and residue management.

- Replace fluids and filters: They might not be flashy, but fluids and filters are some of the most important factors when it comes to maintenance prevention and equipment protection. Make sure to invest in genuine fluids and filters.

- Make use of the grease gun and grease all the grease nipples. If the nipple is damaged, replace it immediately.

- Replace difficult-to-reach fanbelts if you are expecting them to break during the harvesting season.

- Clean and inspect the combine harvester properly.

Don’t forget the technology

- Technology is critical to achieving peak productivity during the harvesting season. It is important to make sure your systems are ready to go with the latest software updates. Consider investing in the latest harvesting technology for greater efficiency.

- Fine-tuning automated settings can help maximise the amount of high-quality grain you harvest. For instance, AFS Harvest Command™ makes harvesting simple by reducing the number of functions producers need to monitor from twelve to just three.

Check with your dealer

You know your equipment best, but your dealer can help you check blind spots to avoid otherwise unseen problems. If you want to make sure you are completely ready for harvest season this year, get your list double-checked by your local dealer.

LET’S GET DOWN TO MAINTENANCE

The maize, sunflower or soyabean headers all are some of the most important components to harvest a crop effectively. If there is wear and tear, it will influence the combine harvester’s performance and some kernels will end on the ground.

The cutter bar

Make sure that the knives, guards, skid plates and hold-down clips are in good working order on the cutter bar. Remember, if you replace the knives, the guards should usually also be replaced. Make sure that the cutter bar (Photo 1) stays in position and that it can move freely. It is also important to inspect the moving parts of the header.

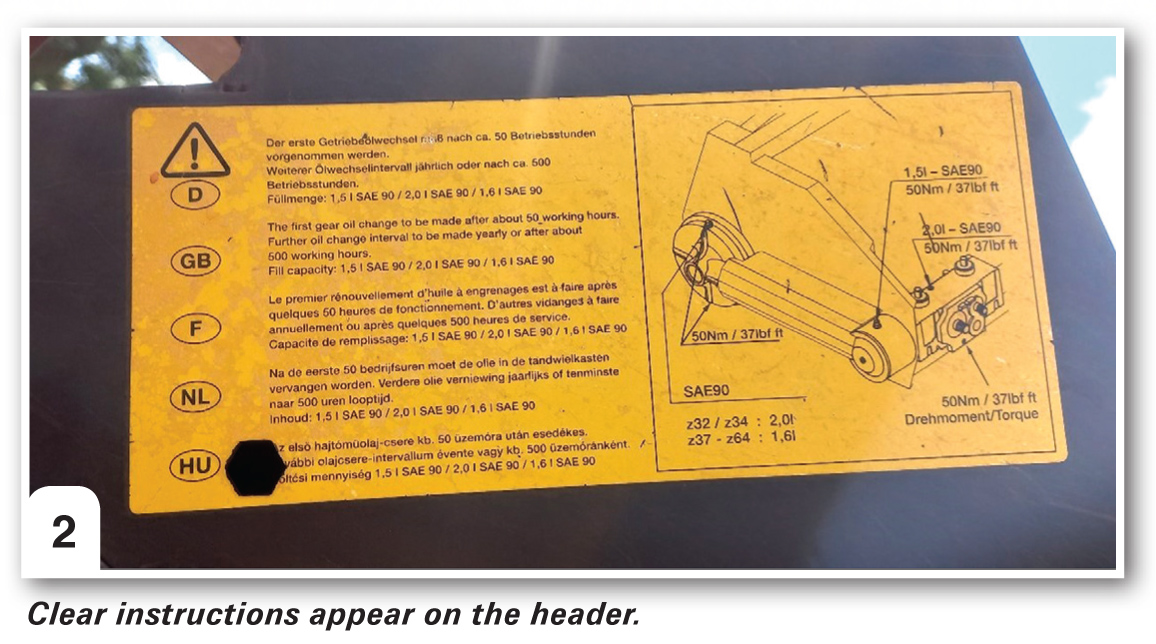

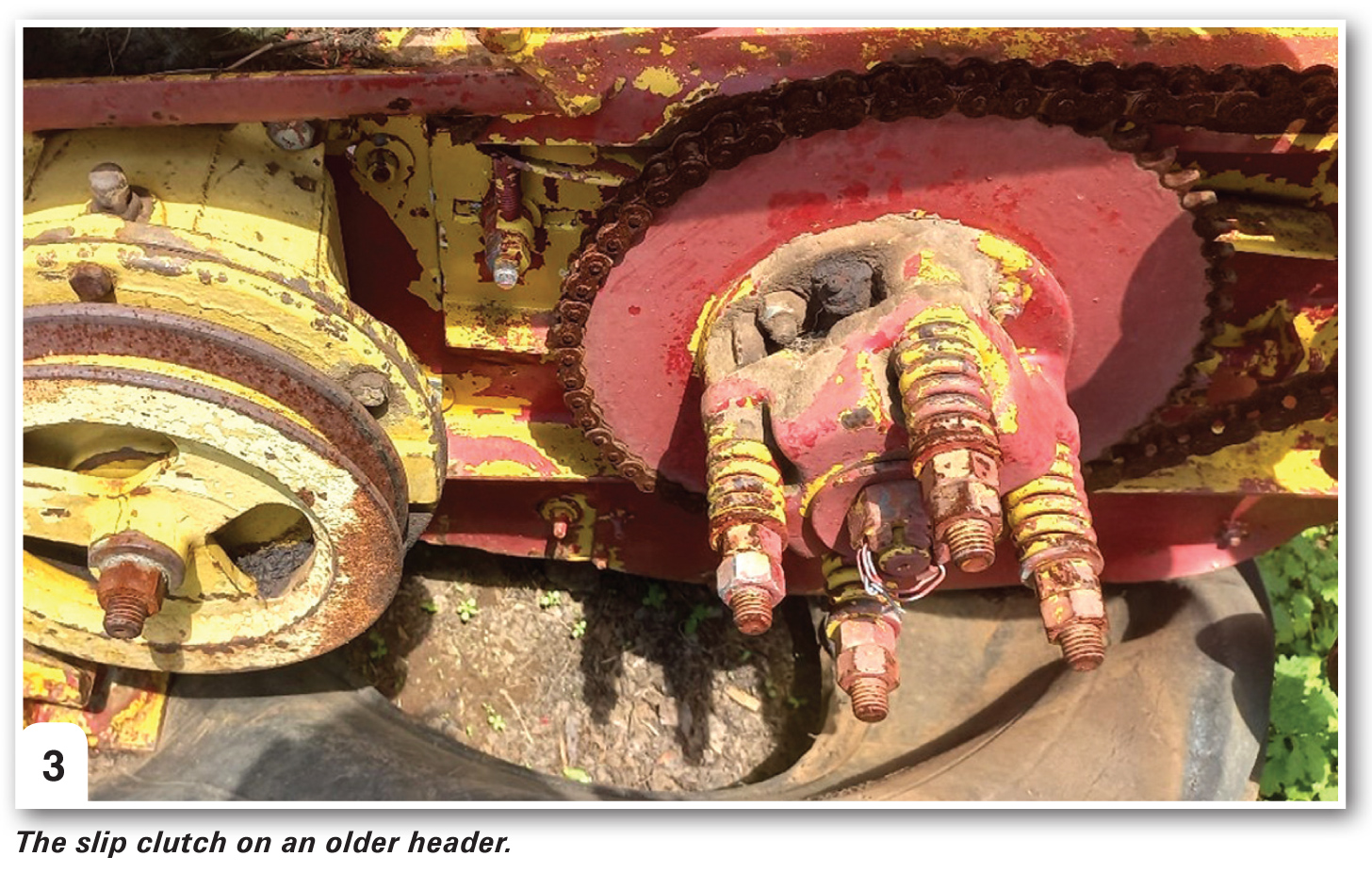

Instructions

- It is important to read the header manual (Photo 2) and to do the maintenance as required.

- Check the oils in the gearboxes, as well as the tension on the fanbelts and driving chains.

- Oil and grease the power shafts.

- Replace the oil in the gearboxes as required. Grease may be a cheap lubrication fluid, but it can save you a lot of money.

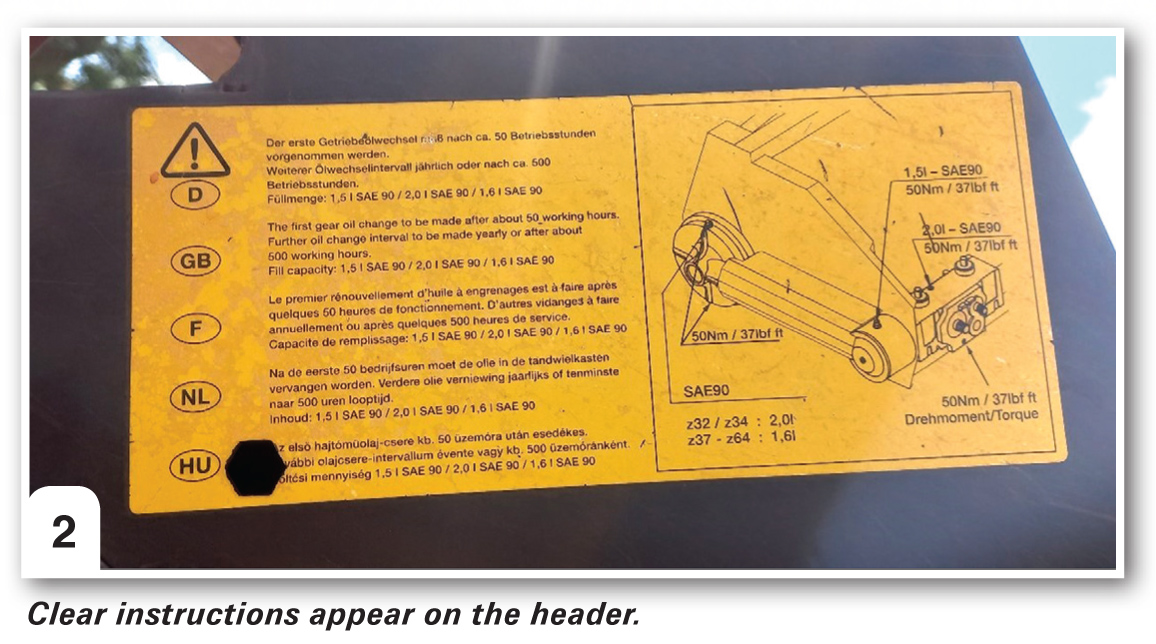

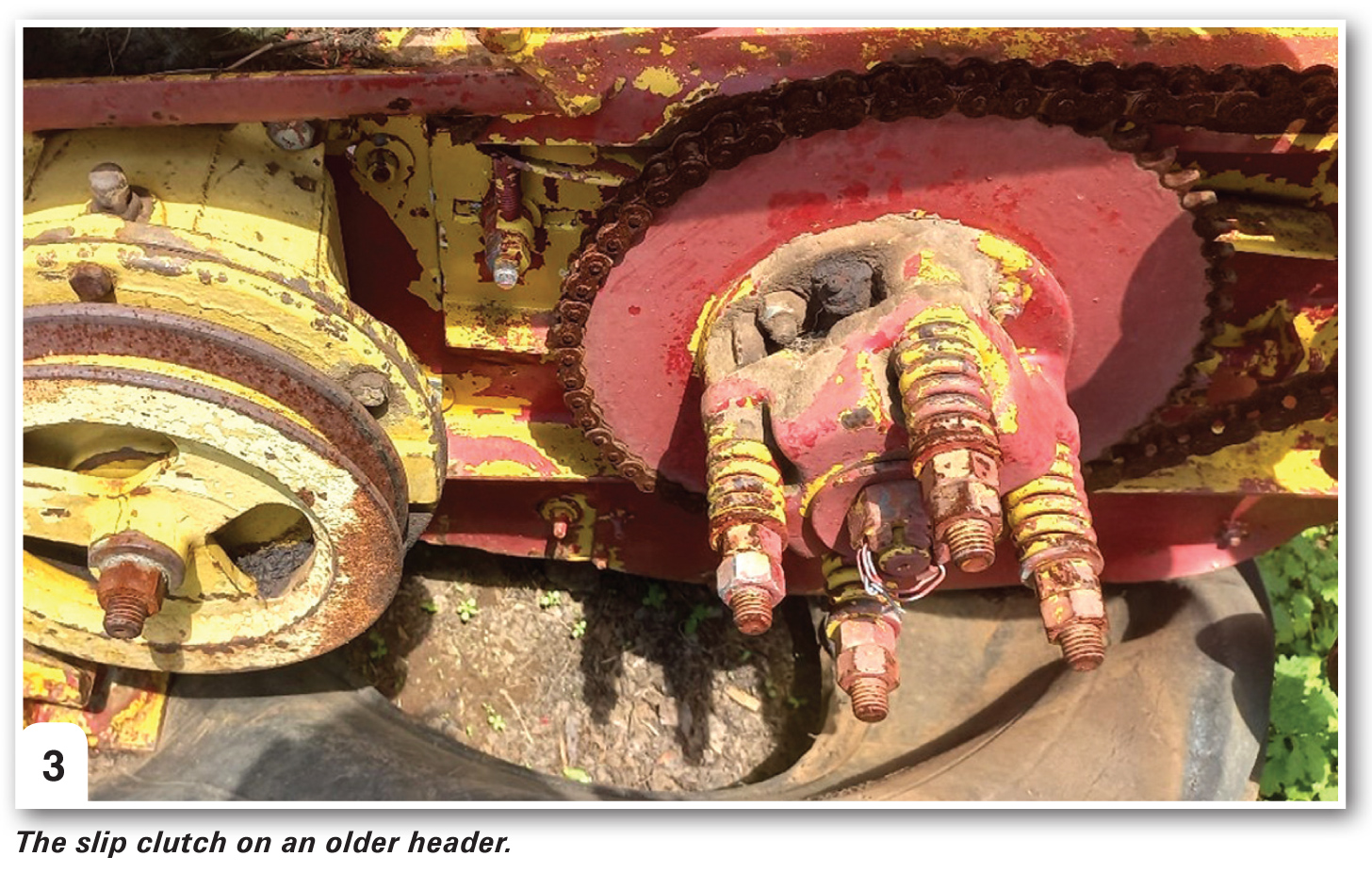

Clutches

If you have an older type of header (Photo 3), checking the different clutches and ensuring that they are set according to the manuals can save you a lot of money.

Maintenance on headers

Sunflower header (Photo 4)

- Make sure that the catch boards are in place and set according to the row widths.

- Ensure that the boards are tightened and set to catch the sunflower heads.

- The cutter bar should be working efficiently.

The feed auger fingers, bushings, plastic guides, pins and sleeves must not be worn out, as this may influence the work of the header. If these components are worn out, the material cannot move effectively from the header to the combine machine.

Maize header (Photo 5)

On the maize header the important points to check are:

- The deck plates must be set to catch the cobs and kernels from falling on the ground. If the deck plates can be adjusted, make sure that they can move freely. Look for wear and tear on the links to adjust the deck plates.

- The gathering chain is the chain that moves the material to the header feed auger. Check the tension on the chain and the wear and tear on the chain and sprockets. Make sure that the springs that keep the tension are free to move and are not rusted. Make sure that the drive gearbox is filled with oil or grease.

If you must replace the gathering chain, consider the one from 360 Yield Centre (Photo 6). It is a gathering chain equipped with brushes to firstly absorb the shock of the heads on the cover plates, and secondly to catch the loose kernels and feed them to the auger. This will help a lot with kernel loss.

If you must replace the gathering chain, consider the one from 360 Yield Centre (Photo 6). It is a gathering chain equipped with brushes to firstly absorb the shock of the heads on the cover plates, and secondly to catch the loose kernels and feed them to the auger. This will help a lot with kernel loss.

- The snapper rollers (Photo 7) are responsible for pulling the plant through the header. Make sure that the snapper rollers are set according to the manufacturer’s norms. Ensure that the speed of these rollers is according to the harvesting speed. In the case of high-density maize, 360 Yield Centre markets a product called a chainroll. This snapper roller tears the plant material so that the material can decompose quicker.

Publication: March 2024

Section: Pula/Imvula

If you must replace the gathering chain, consider the one from 360 Yield Centre (Photo 6). It is a gathering chain equipped with brushes to firstly absorb the shock of the heads on the cover plates, and secondly to catch the loose kernels and feed them to the auger. This will help a lot with kernel loss.

If you must replace the gathering chain, consider the one from 360 Yield Centre (Photo 6). It is a gathering chain equipped with brushes to firstly absorb the shock of the heads on the cover plates, and secondly to catch the loose kernels and feed them to the auger. This will help a lot with kernel loss.