June 2022

| PIETMAN BOTHA, INDEPENDENT AGRI- CULTURAL CONSULTANT |

|

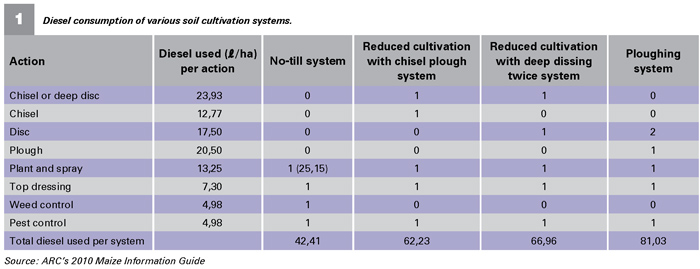

Soil cultivation remains one of the primary cost items in crop farming, with diesel being one of the highest cost contributors. When combined, diesel costs, tractor repairs and maintenance contribute about 20% of the total directly allocatable variable cost of grain production. This makes it important to re-evaluate cultivation practices.

Table 1 shows the diesel consumption related to various soil cultivation systems. This information makes one wonder if diesel usage can be reduced. The only way this can be done is to make sure that cultivation is done correctly and that the correct working depth is found and maintained in order to solve this problem.

WHY IS SOIL CULTIVATED?

BEFORE CULTIVATION

It make sense to decide what cultivation action to implement and to set the goals of each action in advance. One of the main objectives of primary tillage is to remove compaction layers and to break up the soil. To do this meaningfully, it is important to determine if there really are compaction layers and if so, at what depth they occur. This will determine how deep to work.

A penetrometer is the best tool to measure compaction and to decide how deep to work, but a soil profile pit can also be examined to determine the thickness of compaction. However, it is a difficult to determine with reasonable accuracy the bottom of the compacted zone and therefore the effective working depth. The deeper the implement is working, the higher the diesel consumption will be. It therefore makes sense to work only as deep as needed. A rule of thumb to apply is the higher the clay, the shallower one can work and vice versa.

The weed density and their size will surely determine the method of cultivation. The smaller the weed, the easier it will perish. If the weed is large and you want to use a tiller, make sure that the correct shares are used and that they cut or kill the weed. If the weed must be killed, a disc that cuts the field or a plough will work better even though it is more costly. Timing is everything. If weeds grow too big it will be more costly to eradicate.

To manage the cost of cultivation, the moisture content of the topsoil is important. If the soil is too dry the soil will break up into large clods and the tractor will use extra diesel. An extra action will also be needed to break the clods. Working too dry soil will cause increased wear on both the tractor and the implement. If on the other hand the soil is too wet, it will also create problems. If producers want to rip soil that is too wet, the ripper will not break up the soil as anticipated and will create portions in the soil where it has not been loosened properly.

Correct soil content can be determined by digging the soil with a spade. If the soil digs comfortably, the chances are good that the land can be cultivated. A hard dry crust thicker than 10 cm is about the limit, after which the operation should rather be postponed until after a rainy day.

Sandy soil can be cultivated quicker after rain than loamy soil. Normally it can be worked two days after good rain, but for loamy soil rather wait three days. Clay soil's window period for cultivation is small, because it stays too wet for a long time and then dries too quickly again. Timing is everything.

SOIL CULTIVATION

During cultivation, the implements’ working depth must be checked on a regular basis to make sure that the implement is working at the target depth. In the case of ploughing, it can be easily checked in the hollow furrow. With chisel ploughing, the working depth is usually overestimated and needs to be checked with a depth measuring stick.

The rippers’ working depth must be measured in the furrow that is created by the tines and shear of the implement. Remember to first level the soil evenly on the measuring point, step on it slightly and then measure it against the unworked soil. With cultivation the soil is lifted and can create a false impression. Also check the efficiency of the implement by measuring the compaction between the tines.

It often happens that tine implements only pull furrows into the soil and does not break the whole profile. This happens because the tines are spaced too wide or the soil is too wet. A rule of thumb to apply is to space the tines at 70% of the intended working depth. This significantly increases the efficiency of the operation.

Check the shares for wear and tear. The ripper and chisel plough shares wear out and get shorter over time. This causes the implement to work shallower over time because normally a depth control wheel is used on tine implements.

In a cultivation system where there is no crop residues on the surface, it can often lead to surface crusting throughout the season. Crusting again leads to poor water infiltration and eventually water erosion. Runoff water is also lost to plant production and crop yields is lower. Shallow hoeing is effective in breaking up such surface crusts.

An effective way to manage costs is to implement a controlled traffic system. This consist of the tractors staying on the same tracks throughout the production year. Soil compaction is minimised and the fuel consumption of the tractors will be lower.

There are a number of aspects that need to be addressed. It is therefore important to consult an expert in this aspect.

To do soil analysis, a soil profile pit has to be dug.

Publication: June 2022

Section: Pula/Imvula