December 2013

DR ANDRÉ VAN DER VYVER, UNIVERSITY OF PRETORIA

Barley is a short-seasoned, early maturing crop. About half of the world’s crop is used as livestock feed, while the rest is used for human food and for malting. Most beer is made from malted barley.

Malt barley is the perfect combination of starch enzymes, flavours and aromas for brewing and distilling. Some of the principal characteristics used to define malting quality are protein, malt extract, enzyme activity and beta-glucan.

Feed barley is used as animal feed. A rule of thumb is that good malt barley is good feed barley, but the reverse is not true. In general, malt barley commands a premium over feed barley, but yields less.

World barley production

The world’s barley production reached 129,9 million tons (USDA, 2013) during the 2012/2013 season, which is lower than the previous season. The production trend line over the past twelve years is almost stable on a level of 140 million tons, but in the previous three seasons production fell below this trend.

Barley is grown in about 100 countries worldwide, with three regions, namely the European Union (mainly Spain, Germany and France), the Russian Federation and Canada, responsible for more than half of the world’s barley. Canada is the top malt barley producer.

Most of the growth in demand for malt barley and malt during the next five years will be in countries with rapidly expanding beer production. Africa is the largest nation in this regard with a 21% annual growth rate. The rapid growth also means that SABMiller plans to invest up to ,5 billion in Africa over the next five years to build and revamp breweries.

The South African barley industry

In South Africa, barley is mainly planted for malting purposes as there is no significant feed market for barley due to the oversupply of maize. Barley differs from most other agricultural commodities in that there is only one major barley buyer in South Africa, the SA Maltsters; they supply their major stakeholder, South African Breweries Ltd, with malted barley. Barley producers mostly had a guaranteed market, but lately are exposed to price risk – the price of barley is now linked to the wheat price.

Production of barley in South Africa

South Africa’s total annual production of barley is around 225 000 tons to 250 000 tons. Approximately 80% of all barley produced is classified as malt barley. This however, still results in a shortfall of about 75 000 tons of malt barley, which is imported either as malt barley or as malted barley. South Africa is the fourth leading country importing Canadian malt barley and the third leading country importing Canadian malted barley.

Until 1997, the production of barley was almost exclusively limited to the Southern Cape. Production on an experimental basis was only brought to the inland irrigation areas of Vaalharts during 1997. Today the inland irrigation areas produce on average around 75 000 tons on 14 000 ha. The production of barley is mainly concentrated in three irrigation production areas, namely Vaalharts (about 33 000 tons), GWK (about 17 000 tons) and Taung (approximately 7 000 tons).

GWK consists of Douglas (the majority), Rietrivier and Barkley West. Smaller quantities are also grown in the Modderrivier and Hopetown areas, which are typically included in the GWK numbers. Lately some experimentation has also been conducted in the Brits/Koedoeskop irrigation areas, providing approximately 2 000 tons. For all practical purposes, SAB is the only buyer and barley is produced under contract.

A significant yield difference exists between the Southern Cape (dryland) and the Northern Cape (irrigation), but there has been a constant improvement over the years.

Pricing

Pricing

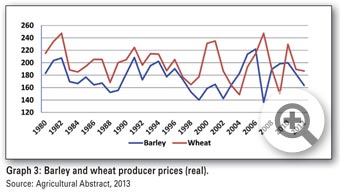

With the Southern Cape historically being the only production area and with wheat virtually the only alternative for producers, the price or profitability of barley production has always been compared or “linked” to that of wheat. Graph 3 illustrates the relationship between the average barley and wheat producer prices deflated with the producer price indices for field crops.

It has only been since the 2011/2012 season that an alternative agreement has been reached between SAB and the producers whereby the price has been linked to the Safex wheat December futures contract. This now enables both the producers and the buyers to price individually and according to their respective price views. Pricing could also take place post-harvesting.

SAB investment

In South Africa, SAB is investing in a new state of the art, R700 million malting plant in Alrode, Gauteng. The new plant will allow it to reduce the amount of malted barley it imports and assist in providing support to small scale black farmers. At present SAB sources about 65% of its barley locally.

Once the new malting plant is completed, this figure is expected to increase to between 90% - 95%. The Caledon plant in the Western Cape (WC) malts about 180 000 tons of barley a year and the old Alrode plant about 42 000 tons a year. The new plant will have a capacity of 130 000 tons of malted barley by its completion in 2015.

It is not possible to competitively deliver Cape barley to the Alrode plant. The expansion of this plant to more than double its capacity, will bring additional production opportunities to inland producers.

The Northern Cape irrigation areas

In the Northern Cape, the total area under barley stands at 39% of the total area under wheat production. This necessarily implies that when a producer decides what to grow, he will base his decision mainly on technical production factors and profitability.

Technical factors will include aspects such as rotational patterns, diseases, improved cultivars and soil quality. Profitability implies a comparison of the potential net income from the production of barley compared to that of wheat. Risk will also be taken into account, meaning that a comparison will be made of the potential for complications occurring during the growth period that will affect the yield of barley, with that relating to wheat. From a production perspective, barley is generally regarded as a more technically challenging crop compared to wheat.

A production cost comparison between barley and wheat

Due to the limited space available, only the budgeted production data of Douglas (supplied by GWK) is listed in this article, but the actuals as well as the data for Vaalharts (supplied by Senwes) are available in the full study.

Table 1 is the budgeted production cost data supplied by GWK (2013). The variable input cost data of GWK was once again used in Table 2. On this basis, net profit is compared in Table 3.

Quality assessment

Fairly unique to the South African environment, grading is done on a sliding scale with multiple intervals and the producers are rewarded for better quality. Aspects such as the percentage of plump kernels, nitrogen levels, moisture levels, screenings and foreign matter are all based on sliding scales. According to SAB (2013), producers were paid on average, R329/ton in the GWK area and R312/ton in the Vaalharts area.

Production and logistics

Interviews with stakeholders revealed many different issues regarding the production process. The more important ones are listed below:

Pests

More than once it was stated that the fact that barley is not susceptible to fusarium is a huge benefit. This is particularly true for those producers that have fusarium problems in respect of their wheat. Barley is also not affected by take-all (vrotpootjie).

Nitrogen application

In the past it was considered cheaper to produce barley, since the nitrogen application was less, 30 kg/ha - 40 kg/ha compared to wheat’s 250 kg/ha. Nowadays, the gap has narrowed and new cultivars could require 130 kg/ha - 140 kg/ha.

Water management

Producers in Vaalharts have specifically mentioned that barley requires better management of water. Directly after being irrigated, the kernels are heavy and if the wind then starts to blow there is a real danger of lodging since the stem is top-heavy. This means that, day or night, the pivot has to be switched off.

Lodging

Lodging appears to be a very contentious issue, particularly from a producer’s perspective. Barley could yield 7 tons - 8 tons, but if lodging occurs it could be down to 5 tons. Despite all the allegations made with regard to lodging, no data has yet been collected. This makes it impossible to quantify the extent of the problem on an industry basis.

Harvesting time

It seems that one of the major benefits for producers is that barley has a slightly shorter production cycle and could be harvested one to two weeks earlier than wheat. This is highly beneficial for producers since it results in better optimisation of their equipment i.e. using less combines and trucks in combination between a barley and wheat harvesting programme.

Feed barley

Feed barley in South Africa is the result of malt barley that is downgraded. Malt barley and wheat command a price of around 50% - 60% premium higher than that of feed grains, mainly yellow maize. Any malt barley that is downgraded to feed barley therefore means a huge loss to the producer. Vaalharts producers estimate feed barley delivered to the silos at 3% - 4%.

Financially promising

Production cost data obtained from GWK indicates that producers earn substantially more from the production of barley than from wheat. Budgeted figures in the Douglas areas show a gross income per hectare of R5 584 per hectare for barley versus R2 246 per hectare for wheat (actual numbers are higher). The compatible numbers for Vaalharts are R7 647 and R4 857 respectively.

When the two sets of numbers are compared, barley is a better proposition (versus wheat) in the GWK area (a gross profitability of 148% higher per hectare) than in the Vaalharts area (57%).

This, however, is not the only benefit, and the benefits of an early maturing crop and fusarium resistance, rank as two of the main additional advantages in a high intensity production environment. There is no doubt that the production of barley requires a higher degree of management skills and commitment.

Lodging and the possibility of a downgrade to feed barley were listed as two of the key problem areas. Despite the 8% deduction by SAB, there is little doubt that there is an adequate financial incentive for the production of malt barley.

References

DAFF (2013). Barley information, Pretoria.

GWK (2013). GWK Kostegids. Maart 2013, Douglas.

Lubbe, F. (2013). Agriculturalist, SAB. Personal interview. 26 March 2013, Kimberley.

SAB (undated). Presentation. The South African Breweries Maltings.

SAGIS (2013). Barley statistics, Pretoria.

Senwes (2013). Senwes produksiekostenorme 2012-wintergewasse: Gars en koring.

11 Julie 2013, Klerksdorp.

Publication: December 2013

Section: Input Overview