THE

GRAIN AND OILSEED INDUSTRY

OF SOUTH AFRICA – A JOURNEY THROUGH TIME

ႃႂ

Station

Capacity (tons) Station

Capacity (tons)

Frankfort

5 800

Ficksburg

2 600

Heilbron

5 800

Middelburg

2 600

Klerksdorp

5 800

Makokskraal

2 600

Reitz

5 800

Moorreesburg

2 600

Bethal

4 800

Potchefstroom

2 600

Bethlehem

4 800

Leslie

2 600

Kroonstad

4 800

Pienaarsrivier

2 200

Bothaville

4 800

Ventersburg

1 800

Kinross

4 800

Kaallaagte

1 800

Senekal

4 800

Koster

1 800

Rendezvous

4 800

Leeudoringstad

1 800

Lindley

4 800

Makwassie

1 800

Balfour

3 000

Val

1 800

Clocolan

3 000

Westminster

1 800

Ventersdorp

3 000

Davel

1 800

Vermaas

3 000

Standerton

1 800

Vrede

3 000

Settlers

1 750

Coligny

2 600

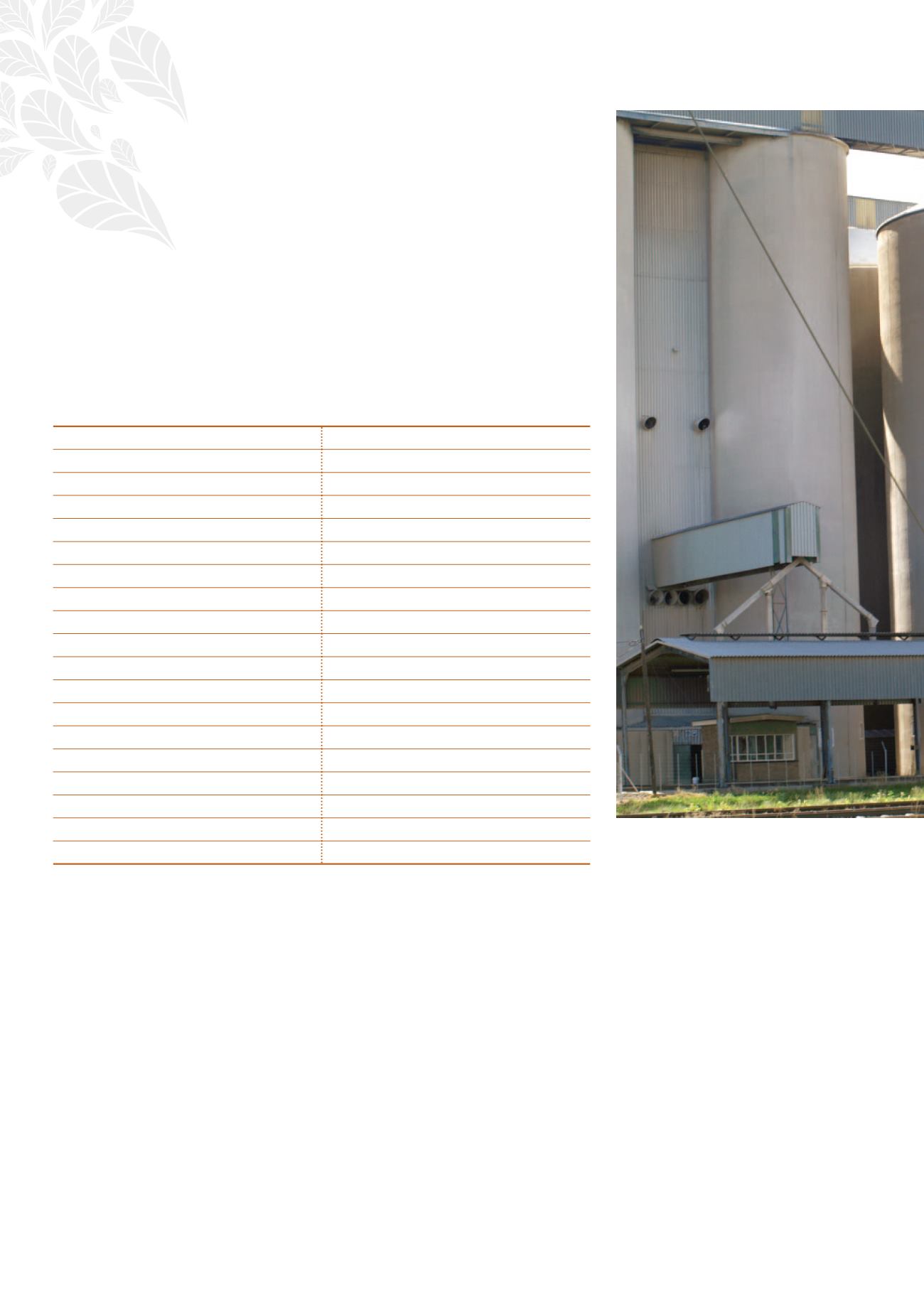

producers until it was delivered or dispatched to buyers. Because storage in the

open (often on the platform of the railway station) caused material problems with

contamination and quality, large corrugated iron stores were constructed in which

the bags of grain were stored.

The increase in production during the early 1920s and the requirements regarding

the weighing, cleaning, grading and storage brought about by increased exports em-

phasised the storage problem. At that stage Canada and the USA were already using

silo storage and a delegation was sent there to investigate this method. On the ba-

sis of this investigation, as well as the report by the Clark Committee, South African

Railways and Harbours (SAR&H), which was part of the government administration,

built two silos – one at the Durban harbour with a capacity of 42 000 tons, and one of

30 000 tons at the Cape Town harbour.

The SAR&H also started constructing silos along railway routes and by 1924

the following silos (later commonly known as the Railways silos and then as the

B silos), with a total storage capacity of 101 850 tons, had already been constructed

in the interior:

These silos received, graded, weighed, cleaned and stored only grain, and did not

trade in grain themselves.

Initially, grain was delivered at the silos mainly in sacks, but also to an extent in

bulk. The way in which the grain in silos was managed had several benefits, includ-

ing certainty with respect to grade and mass, the possibility of guarantees by way

of grain vouchers and a reduced risk of losses during the loading process.

Storage at silos initially encountered considerable problems and the safe and

effective storage of maize was a source of concern for the Maize Board and the

government from the earliest days. The problems experienced led to the govern-

ment ordering an investigation into the storage of maize in 1945. As a result of

this the Maize Board sent a delegation overseas in 1949 to investigate methods

of bulk handling in Australia.

In 1951 the Maize Board allocated an amount of R300 000 for the construction of a

grain silo at Lichtenburg. The bulk store that was constructed was commissioned

in 1953 and was the forerunner of the movement to construct bulk handling facili-

ties for maize in South Africa.